workshop

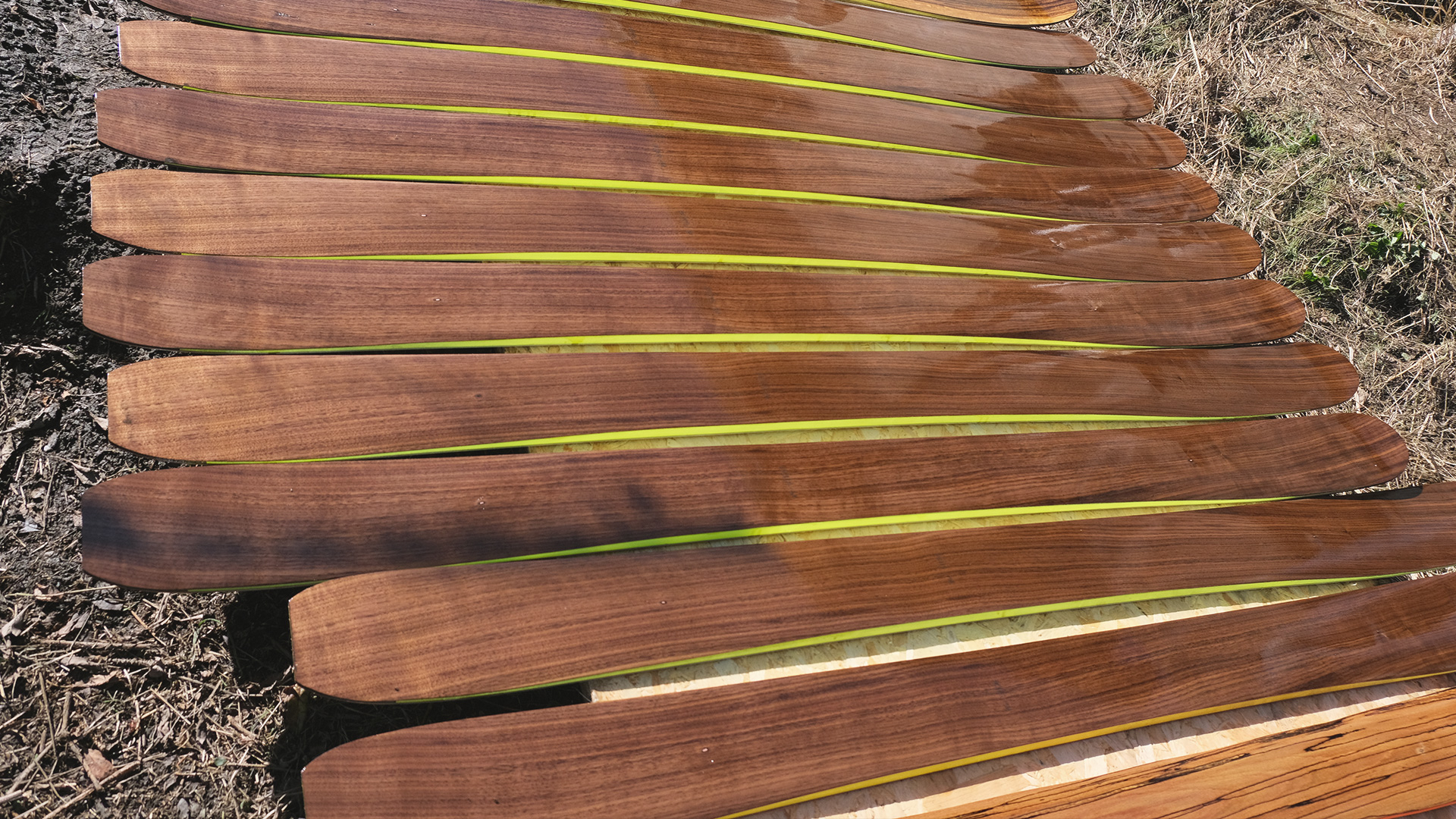

precision-built skis

Every ski, snowboard, and deck is made here. This is where curiosity and natural materials combine, and where every detail is guided by performance, sustainability and innovation

Machines with Heritage

Each machine in our workshop isn’t just a tool—it’s a piece of history, chosen for its precision, durability, and connection to traditional craft. Most of them are older than me and already put in a good lifetime of work.

CNC Router & Dragknife – Modern precision meets a traditional cutting technique. Used to shape molds, templates, and veneers with hand-crafted accuracy at scale.

Laser Engraver – Marks topsheets with a permanent, natural logo or design, echoing the pride and detail of classic hand-carved skis.

Wadkin AGS12 & Robinson YDT Bandsaw – British-made woodworking classics, perfect for cutting wood cores and veneers with smooth, reliable precision.

Wadkin 450mm Three-Phase Planer Thicknesser – Ensures uniform core thickness and flatness, forming the foundation for torsion, flex, and performance.

Wintersteiger Base Grinder – Industry-standard for smoothing and tuning bases, reflecting the care of early ski tuners.

Hand-Built Ski Press & Custom Clamping System – Inspired by traditional presses but adapted for natural materials like hemp, flax, bamboo, and cork. Preserves the artisanal feel while maintaining precision and consistency.

The Journey to the Workshop

The workshop is on the Glyndŵr Way. It’s six miles from my home in Abercegir to Glantwymyn. Over the hills, on foot or by bike, through the Welsh weather, with the dog.

The journey is a good commute; it’s part of the rhythm. Mist in the morning, shifting light over the hills, and the quiet of nature become a mental warm-up before a day of precision work. It’s a reminder that craftsmanship is as much about patience, observation, and presence as it is about tools and technique. Balancing the technical and creative, its about how it feels in the end.

Stages of Construction – In Detail

Design & Mold Creation

read moreEvery ski begins as a concept.

CNC templates and custom sidewall molds guide the pressing process, ensuring that every curve, edge, and camber is exactly as intended.

Core Preparation

read moreWe select natural woods like ash for stiffness, poplar for balanced flex, or paulownia for lightness. Blanks are cut with our bandsaws and planed to exact thicknesses using the Wadkin planer. Sidewalls are shaped to fit precisely, setting the stage for reliable flex and torsion.

Layering & Lamination

read moreLayers of hemp, flax, bamboo, and carbon stringers are applied in precise sequences for strength, vibration damping, and torsional performance. Cork spacers in the tips and tails enhance shock absorption. Eco-resin binds the layers, while the clamping system ensures perfect alignment.

Pressing & Shaping

read moreThe hand-built press applies heat and pressure to bond all layers. Sidewalls and tips are held perfectly in place by the clamping system, forming a cohesive structure. After pressing, skis are measured to confirm camber, flex, and torsion match the design.

Finishing

read moreBases are ground with the Wintersteiger, edges trimmed, and topsheets laser-engraved. Boards are sanded, oiled, and waxed, revealing the natural beauty of wood and fibers.

Testing & Quality

read moreEvery board is inspected visually, flex-tested, and occasionally ridden in real conditions to confirm performance. Nothing leaves the workshop unless it meets the highest standards.

The Natural Journey

We began with conventional methods—nylon topsheets, plastic sidewalls, fibreglass laminates, tip and tail spacers, and sublimation printing. Over time, we evolved toward the Natural approach:

Wood cores and veneersflex naturally

Hemp and flax layers for vibration damping and torsional strength

Cork tips and tails for shock absorption

Eco-resins and natural oils for a sustainable, beautiful finish

Every choice reflects a commitment to performance, sustainability.

Sustainability at the Core

From day one, our workshop has run on 100% renewable energy, powering every saw, planer, press, and laser. Each material is carefully selected not only for its performance but also for minimal environmental impact, ensuring that every board we make respects the planet as much as it does the rider. It’s not perfect and there’s always room for improvement and refinements. More solar panels, cleaner materials and converting the van to electric would all be good next steps.